Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: FY-850

Brand: Feiyang

Drive Mode: Chain

Roller Fixer: Middle Plate Welded

Diameter Of Shafts: 70mm

Brand: Feiyang

Voltage: 380V50Hz3Phse

Frame Thickness: 16mm

Material Of Rollers: 45# Steel, Surface Hard Chromium Platin

Packaging: Naking

Productivity: 50 set/month

Transportation: Ocean,Land

Place of Origin: China,Hebei

Supply Ability: 50 set/month

Certificate: CE

Port: Tianjin Port,Qingdao Port

Payment Type: L/C,T/T

Incoterm: FOB,CIF

At present, the most advanced color steel equipment model is corrugated board equipment. The machines are all equipped with automatic PLC control system, mainly hand touch screen and digital display. The mold is made of Cr12, which is durable and has a long service life. Strengthening the indenter and the universal pressure plate, it is convenient to replace different main tile molds and special-shaped tile molds. The color steel equipment is suitable for producing various types of color map corrugated board.

Here is the example of machine for your reference:

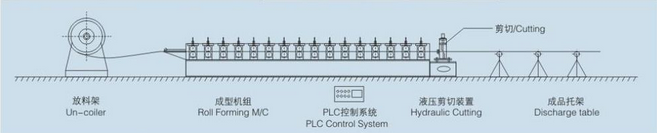

Checking Process of the Corrugated Steel Sheet Forming Machine

manual uncoiler - Roll Forming Machine - computer control system - hydraulic control system - cutting system - output table

Product parameters

(1). Suitable material to process: PPGI coil and GI coil;

(2). Thickness of the plate: 0.2-0.8mm;

(3). Width of the plate: as per profile drawing;

(4). Effective area for use: as per profile drawing;

(5). Productivity: 8-15m/min;

(6). Roller stations: around 14 rows;

(7). Diameter of the shaft: φ70mm;

(8). Material of roller: 45# steel with CNC machining, plated hard chromium surface;

(9). Material of main shaft: 45# steel with grinding process and then slack quench processed;

(10). Frame: welded with 350H section steel;

(11). Wall panel thickness: 16mm;

(12). Main motor power: 4KW;

(13). Hydraulic station power: 4KW;

(14). Main electrical control system: Panasonic PLC, Delta frequency changer, Delta touch screen, Omron counter;

(15). Material of cutter: Cr12MoV with hard treatment;

(16). Driving mode: single chain 1 inch;

(17). Power supply: 380V, 60HZ, 3 PHASES;

Manual Uncoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

Coil Feeding Part

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working

Cutting device

Advanced Hydraulic drive,automatic punching and cutting after forming, no distorting or wasting,high level safty factor.

Including cutting tools,hyraulic pump,Cutting Machine.

About our company:

Cangzhou Feiyang Machinery Co.,Ltd is a company specialising in the filed of cold roll forming machines and metal sheet processing.We have been establishing and keeping good business relationship with more than 70 countries of worthy clients all over the world, mainly locating in East Europe, Middle East, South and West Asia, Africa and South America. We are proud of our own professional team with more than 18 years` experience in customized design and manufacture, installation and test, technical solution and after services. All the machines are with international quality standards and great after-sales services.

Main product catagories Color Steel Roll Forming Machine, classical glazed tile forming machine, Double Layer Roll Forming Machine,C/Z purlin machine for light steel structure building, floor deck forming machine, Sandwich Panel Production Line,fast guardrail roll forming line and various kinds full-automatic cold bending roll forming equipment.We do firmly believe :technological innovation ,making every detail of the product perfect is our ambition ever.

Any other questions please send inqury to us

Product Categories : Roofing Sheet Roll Forming Machine > Corrugated Roof Roll Forming Machine

Home > Products > Roofing Sheet Roll Forming Machine > Corrugated Roof Roll Forming Machine > Corrugated roofing sheet roll forming machine

Send Inquiry

Ms. Wendy

Email:

Send Inquiry Tel:86-0317-7667606

Fax:0086-0317-7667606

Mobile Phone:8615128799105

Email:

Address:Baozi Village,Nanxiakou Town,Dongguang County, Cangzhou, Hebei

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.